Brief description:

Dewatering sieve, the main function is dehydration, desilting, deintercalation, can be used in sand washing plant sand washing, coal preparation plant slime recovery, mine tailings dry discharge, etc., so it is also called sand dewatering sieve, mine dewatering sieve, Slime dewatering screen, tailings dewatering screen, etc.

Tailings dewatering sieve is also called tailings dry discharge sieve. In addition to the various excellent performance and functions of ordinary dewatering sieve, tailings dry discharge sieve is often used in conjunction with thickener to perform tailings dry discharge. It is the best dewatering sieve and tailings. Mine dry row equipment.

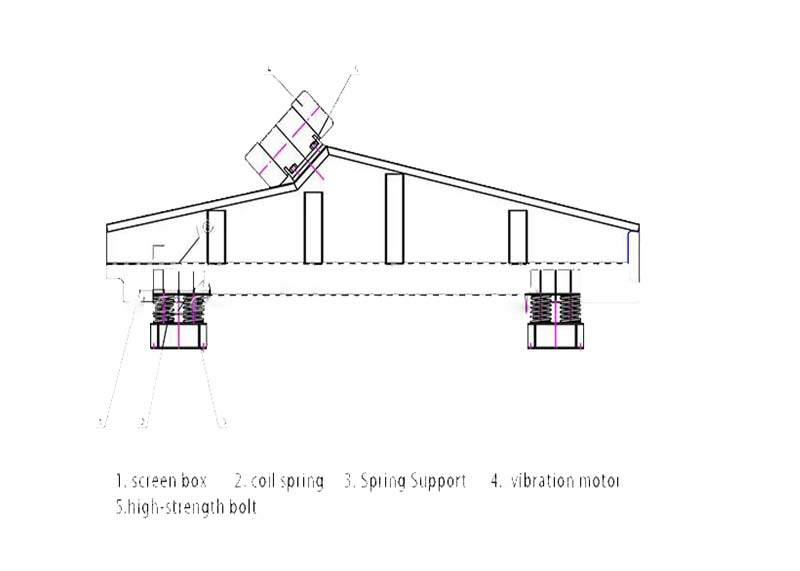

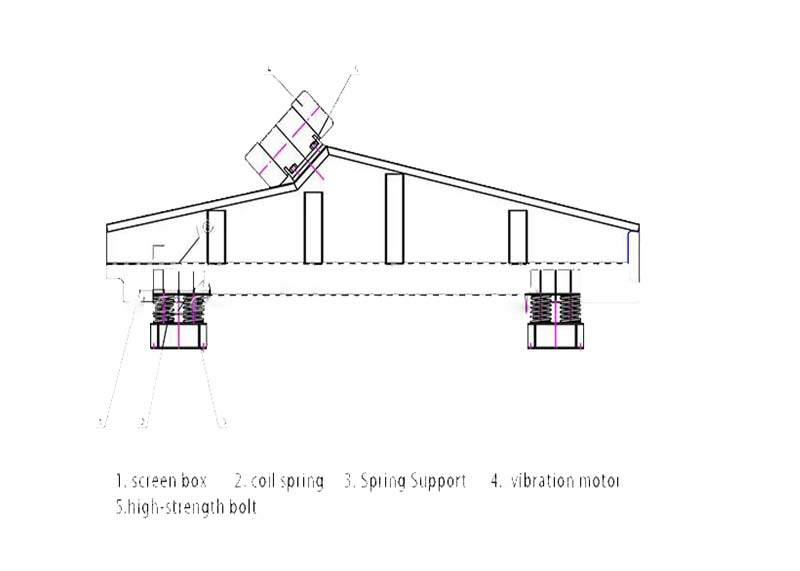

Working principle:

The dehydration screen adopts double electrode self-synchronization technology, universal eccentric block and adjustable amplitude vibrator. It is mainly composed of screen box, vibration exciter, support system and motor. Two unconnected vibrators are driven by the tape coupling shaft to perform synchronous reverse operation. The centrifugal forces generated by the two sets of eccentric masses are superimposed on the component of the vibration direction, and the reverse centrifugal force cancels out, thereby forming a single excited vibration To make the screen box reciprocate linearly.

Features:

1.Waterproof motor

Compared with the traditional process, theGaofu company new-type dry-line dewatering process has the advantages of small investment, simple process and small area, which is convenient for the system process layout.

2.Low cost investment

Compared with the traditional process, theGaofu company new-type dry-line dewatering process has the advantages of small investment, simple process and small area, which is convenient for the system process layout.

3.Continuous dewatering operation

Professional design of the frequency, amplitude, low-power source for a variety of dewatering needs 24-hour continuous operation.

4.Large capacity

V-screen design, -5 degree celsius screen surface slope dewatering, dewatering screen with low water, high efficiency, large capacity per unit area.

5.Long service life

High wear-resistant screen plate long life, modular assembly design, easy replacement, cost savings, screen mesh size can be selected according to requirements.

6. Low noise and easy maintenance.

7. Reasonable structure, strong and durable.

8. Good dehydration effect, safe and reliable.

9. Large screening capacity and high screening efficiency.

10. Light weight, easy disassembly and assembly, easy maintenance, no sudden segment spring.

Technical parameter

|

Model |

Angle(.) |

Mesh size(mm) |

Input capacity(t/h) |

Power(kw) |

Total weight(t) |

|

TS1036 |

-5~-3 |

0.3~0.6 |

10~35 |

2×1.1 |

3.8 |

|

TS1236 |

-5~-3 |

0.3~0.6 |

18~65 |

2×2.4 |

4.5 |

|

TS1536 |

-5~-3 |

0.3~0.6 |

30~90 |

2×3.1 |

5.7 |

|

TS1838 |

-5~-3 |

0.3~0.6 |

40~120 |

2×7.5 |

6.6 |

|

TS2138 |

-3~0 |

0.3~0.6 |

60~150 |

2×7.5 |

8.2 |

|

TS2538 |

-3~0 |

0.3~0.6 |

80~200 |

2×11 |

11 |

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.