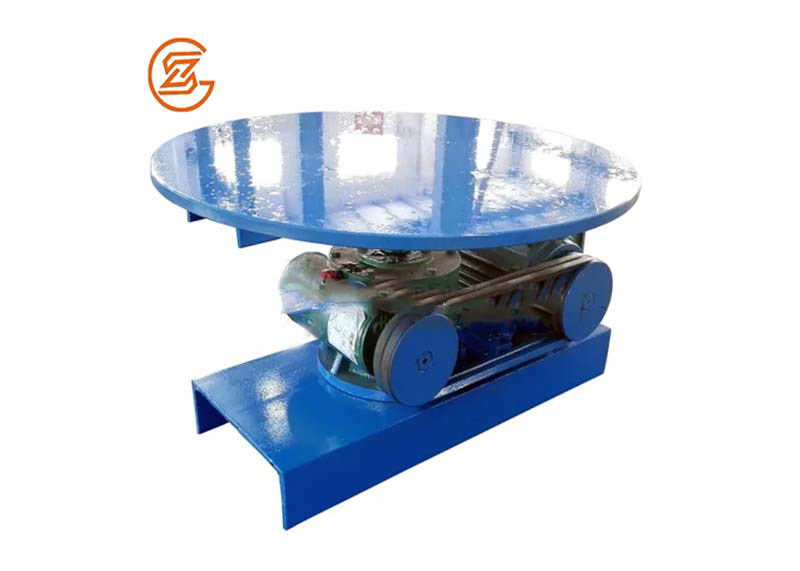

Introduce of Disc Feeder

Disc feeder is of suspension opening type, suitable for feeding the power material with grain size less than 20mm. It is hung above bottom opening of fine-ore bin. The quantity fo ore feeding is adjusted through adjusting the position of scraper.

Disk Feeder is widely used as a continuous volume of charging equipment, can evenly and continuously material will be fed to the next equipment, the feed quantity can be adjusted, can feed powder, small bulk material (such as coal, clay and so on), is the general mill, dryer used equipment.Among them, DK for hanging open, DB for closed type. Disk feeder is widely used in metallurgy, mining, building materials, coal, electric power and other industries a variety of non viscous material feed.

Application of Disc Feeder :

Disk feeder is a cubage measuring feeding equipment, it can be uniform, continuous material will be fed to the next process, and can bear larger cabin pressure. As a fine-grained material feeding equipment, suitable for conveying powdery material, shape or a small state of various non viscous material, such as coal, cement, clinker, limestone, shale, coal gangue, clay powder, granular or lump material. Can be widely used in gold mining, chemical plant, construction and machinery casting workshop for uniformly continuous, quantitative material feeding and proportioning of. The machine has the advantages of simple structure, convenient adjustment, superior performance.This machine is suitable for conveying material particle size is not more than 50mm, not suitable for conveying viscous, flowable material and the mobility of the very good material.

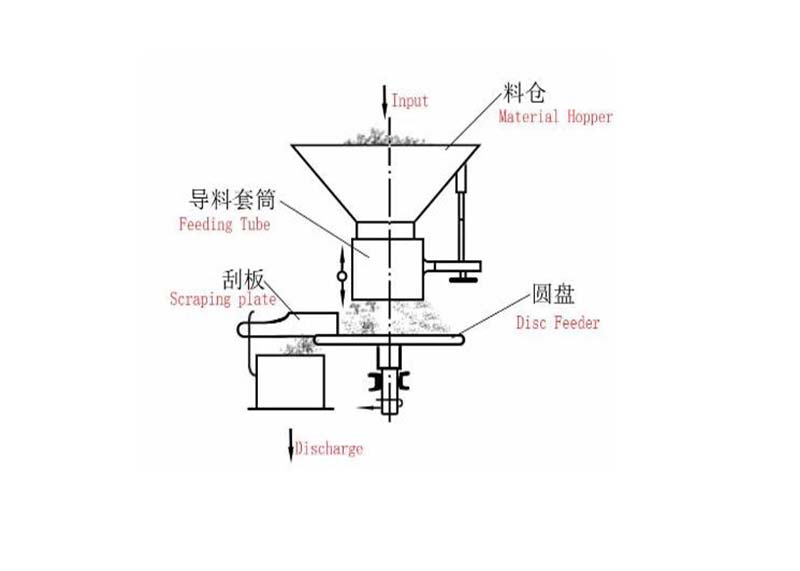

Structure of Disc feeder

Disk feeder for hoisting, closed. Mainly for reducing air leakage or dust system, so as to decrease the environment pollution to the minimum degree. Disc feeder main body is rotated about a vertical axis disc. There is a central disc is connected under the hopper mouth height adjustable blanking sleeve material, material from the sleeve and disc gap leakage dispersion, and scraper material from the disc scraping down. Feed amount can be changed by cutting sleeve and disc gap size and the discharge position to adjust. With the observation window, can be readily observed material feeding and running situation of the equipment.

Technical parameter:

|

Model |

Disk diameter(mm) |

Capacity (ton/h) |

Feeding size |

Power(kw) |

Weight (kg) |

|

Dk6 |

600 |

0.6-3.9 |

25 |

1.1 |

403 |

|

DK8 |

800 |

1.4-7.6 |

30 |

1.1 |

555 |

|

DK10 |

1000 |

2.5-16.7 |

40 |

1.5 |

827 |

|

DK13 |

1300 |

4.2-27.9 |

50 |

3 |

1150 |

|

DK16 |

1600 |

7-48.6 |

60 |

4 |

2125 |

|

DK18 |

1800 |

9.2-60 |

70 |

5.5 |

2900 |

|

DK20 |

2000 |

13.6-38 |

80 |

5.5 |

3140 |

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.