Description:

GZ D-Discharge Screen is a multi-purpose new screening machine that changes the original dual-motor structure and uses a single horizontal vibration motor. Variety of adjustment ways for movement of materials on screen surfaces. Material can be discharged directly, so the handing capacity is greater.Especially the SYM-1000 screen,which has 24 meshes,performs outstandingly in the producing of instant noodles,removing impurity,cleaning,screening and loosing of wheat flour,it’s rate can reach 350kg/150 s,it’s can be raise the highten of inlet and outlet according to the customer’s requires.

Salient Feature:

1.Simple structure, flexible auction ,large handing.

2.Fully enclosed structure,no flying dust,low noise,convenient to clean.

3.Sieving materials quickly,Easy to replace the net.

4.360°degree adjustment of top outlet which can be easy to install.

5.New screening structure,tightly screening and long service life.

Application:

GZ D-Discharge screen is extensively used in flour,starch,washing powder,metal powder,additives,Chemical,powder rough screening accuracy and big processing capacity are easily combined with production line.you have much more choice for both 600mm and 1800mm.

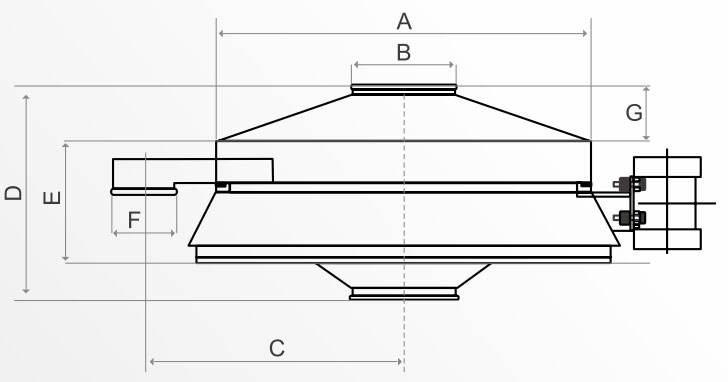

(GZ Direct Discharge Screen Size Indication)

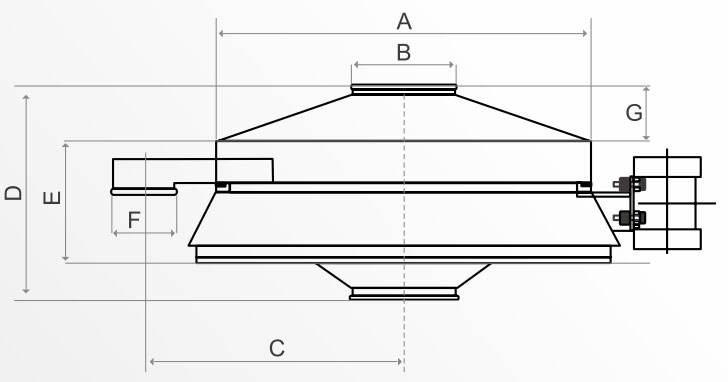

(GZ Direct Discharge Screen Size Indication)

Technical Parameter

|

Model |

A |

B |

C |

D |

E |

F |

G |

|

GZZP-600 |

600 |

150 |

380 |

560 |

325 |

120 |

80 |

|

GZZP-800 |

800 |

200 |

540 |

600 |

350 |

125 |

90 |

|

GZZP-1000 |

970 |

250 |

640 |

640 |

350 |

150 |

100 |

|

GZZP-1200 |

1170 |

250 |

700 |

700 |

400 |

180 |

120 |

|

GZZP-1500 |

1470 |

250 |

760 |

760 |

440 |

200 |

120 |

Size Instruction

|

Model |

Power(Kw) |

Sieving Diameter (mm) |

DimenionL×W×H (mm) |

|

GZZP-600 |

0.12 |

520 |

740×600×560 |

|

GZZP-800 |

0.18 |

720 |

1010×800×600 |

|

GZZP-1000 |

0.18 |

890 |

1200×970×640 |

|

GZZP-1200 |

0.25 |

1090 |

1430×1700×700 |

|

GZZP-1500 |

0.55 |

1390 |

1780×1470×760 |

FAQ

1. What’s are you mainly specialized in?

Our company is a professional manufacture of vibrating equipment(like:Rotary vibrating screen,Linear vibrating screen,Ultrasonic vibro screen,Tumbler Screen,Lab Test Sieve etc);Conveying Equipment(like:screw conveyor and so on);honey process equipment;grain sieving equipment.we have been in this filed for 20 years.

2. What’s row material name? Bulk density(kg/m³)and water content(%)?

For example:Powders,Granular,Lump etc.

3. What’s capacity your required kw/h?

10t/h, 50t/h and 100t/h etc.

4.What’s main purpose of purchasing our machine?

Aim of using: Grading or Getting rid of impurity/Filtration/Grading

5.How many layer do you need? And what’s mesh size for each layer?

Single layer or Multi-layer is supported to be customized by your requirements.

6.What’s usually Voltage&Frequency in your city?

Various power voltage:110V 200V 240V 380V 415V 450V 550V

Power Frequency:50HZ 60HZ or Single phase electricity

7.What’s material for machine as your need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Our service

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customer’s meet any question,we supply the profesional solution.

4.Provide assembly instruction,technical date and related soft copies or video to ensure customer could install and debug by themselves.