Brief Description

High-frequency transducer of Ultrasonic vibrating screening with 38KHz and then puts it into mechanical vibration with 38KHz and attains the purpose of superfine powder.This system uses a low amplitude,high frequency ultrasonic vibrating wave (mechanical wave )on the sieve mesh by the traditional vibrating sieve to improve the sieving abilities of superfine powder.This product is suitable for the users who demand the high additional value and fine powder.(It’s widely used in food,harmaceutical ,Chemical,grinding material,Metal powder,Electron powder,Battery material etc.)

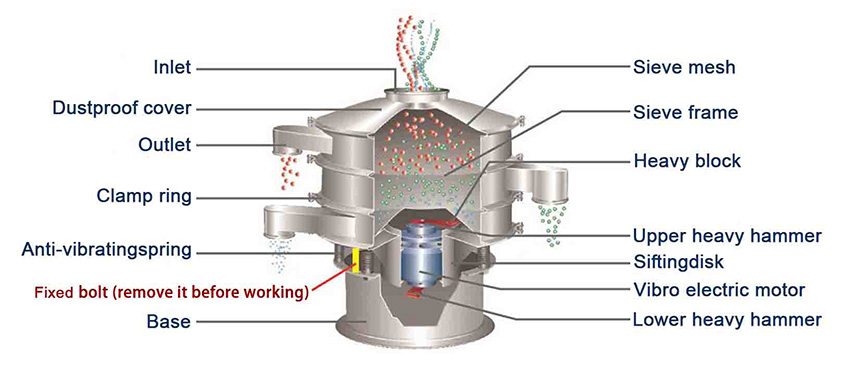

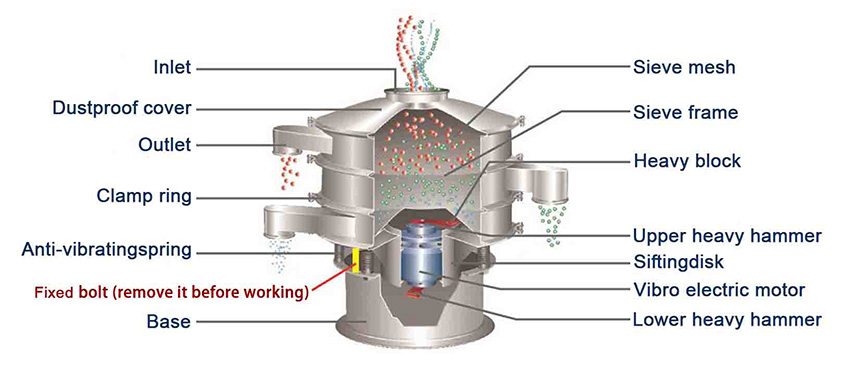

Working Principle

The function principle of ultrasonic vibrating screen is adding an ultrasonic transducer device on the screen surface of 3-D vibro separator and filter.This device can make the screen surface superpose ultra high frequency vibration energy.so that it can keep clear of mesh to prevent clogging and achieve the ideal screen situation. Ultrasonic vibrating screen is usually used in screening Ultra-fine powder which the ordinary vibration screen can not solve.

Feature & Benefits

1.Sieving accuracy can be increased by 1-70%,and output can be increased by 0.5-10 times.

1.High-precision screening can be achieved at the same time ,control of a narrow size range.

2.Effective prevention of screen blockage

3.Really solving the problem of a strong absorption easy to reunite/ high static, high precision etc.

4. Ensure that the characteristics of the screening material unchanged.

5.The Ultrasonic transducer has high-energy conversion rate.

6.24 hours continuous operation,easy to clean ,long screen life.

7.Easy for assembly & De-assembly for cleaning & change over of screens

Technical Parameters

|

Model |

Screenarea (mm) |

Layer |

Mesh Size(mm) |

Power

(kw) |

Vibration Time

(rpm) |

GZ-400-1S

GZ-400-2S

GZ-400-3S |

Φ350 |

1-3 |

0.25-50 |

0.18 |

1440 |

GZ-600-1S

GZ-600-2S

GZ-600-3S |

Φ550 |

1-3 |

0.25-50 |

0.25 |

1440 |

GZ-800-1S

GZ-800-2S

GZ-800-3S |

Φ750 |

1-3 |

0.25-50 |

0.55 |

1440 |

GZ-1000-1S

GZ-1000-2S

GZ-1000-3S |

Φ920 |

1-3 |

0.25-50 |

0.75 |

1440 |

GZ-1200-1S

GZ-1200-2S

GZ-1200-3S |

Φ1120 |

1-3 |

0.25-50 |

1.1 |

36.5KHz |

GZ-1500-1S

GZ-1500-2S

GZ-1500-3S |

Φ1420 |

1-3 |

0.25-50 |

1.5 |

36.5KHz |

GZ-1800-1S

GZ-1800-2S

GZ-1800-3S |

Φ1720 |

1-3 |

0.25-50 |

2.2 |

36.5KHz |

FAQ

1. What’s row material name? Bulk density(kg/m³)and water content(%)?

Em:Grain,Liquid,Sand......

2. What's capacity of screw conveyor that you want?

20t/h, 50t/h and 100t/h etc.

3.What’s main purpose of purchasing our machine?

5m, 10m, 15m and 20m etc.

4.How many layer do you need? And what’s mesh size for each layer?

Single layer or Multi-layer is supported to be customized by your requirements.

5.What’s usually Voltage&Frequency in your city?

Various power voltage:110V 200V 240V 380V 415V 450V 550V

Power Frequency:50HZ 60HZ or Single phase electricity

4.How many layer you need? And what’s mesh size for each layer?

Single layer or Multilayer is supported to be customized by your requirements.

5.What’s material for machine as your need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.

4.Provide assembly instruction,technical date and related soft copies or video to ensure customer could install and debug by themselves.