Description:

The screw feeder is a new generation of products that integrates the stable flow of powder materials, weighing and quantitative control; it is suitable for continuous measurement and batching of powder materials in various industrial production environments; it uses many advanced technologies and reliable operation , High control accuracy; Especially suitable for continuous measurement and batching of powder materials in building materials, metallurgy, electric power, chemical industry and other industries. In other industries, it is suitable for horizontal or inclined transportation of powdery, granular and small lump materials, such as coal mines, ash, slag, cement, grain, etc., the material temperature is less than 200 ℃. It does not transport materials that are easily deteriorated, have high viscosity, and are prone to agglomeration.

Working principle :

The screw feeder detects the weight of the passing material through the weighing bridge to determine the weight of the material on the tape. The digital speed sensor installed at the tail continuously measures the running speed of the feeder. The pulse output of the speed sensor is proportional to The speed, speed signal and weight signal of the feeder are sent to the feeder controller together, and the microprocessor in the controller is processed to generate and display the cumulative amount / instantaneous flow. The flow rate is compared with the set flow rate. The output signal of the control instrument controls the frequency converter to change the drive speed of the feeder, so that the flow rate of the material on the feeder changes, and is close to and maintained at the set feed flow rate to achieve quantitative Feeding requirements.

Structure:

1. The connection between the screw shaft and the hanging bearing, head and tail shaft adopts the embedded tongue type, no axial movement is required for installation and disassembly, and maintenance is convenient. , Long mandrel, Less hanging, Less fault points

2. The variable diameter structure is used to increase the volume of the hanging bearing to avoid contact between the hanging bearing and the material. The life of the hanging bearing can reach more than two years.

3. Each transmission part adopts floating connection method, and the hanging bearing is a universal joint structure, so that the spiral body, the hanging bearing and the tail assembly form an integral rotating floating body, which can freely rotate and avoid with the conveying resistance within a certain range without jamming. No blocking.

4. The head and tail bearing seats are all outside the shell. All bearings adopt multi-layer sealing and matching sealing technology, and the bearing has a long service life.

5. Compared with other conveying equipment, the screw feeder has the advantages of small cross-sectional size, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation and easy maintenance.

Features:

Features:

1. Dedicated to the measurement and control of powdery materials.

2. The feeding screw has a unique steady flow structure, and the material powder sinks evenly on the entire feed inlet section, which is not easy to form an arch and is not easy to punch.

3. Cycloidal pin gear motor ensures long-term stable operation.

4. Stable flow spiral adopts variable pitch structure and outlet overflow method, which effectively solves the problem of material blanking (output> 60T / H adopts double-tube stable flow).

5. The measuring screw scale adopts three high-precision sensors (tensile force) to directly weigh the structure, which successfully solves the error caused by lever weighing and greatly improves the measuring accuracy.

6. Using digital acquisition module, the effective resolution is up to 1 million; the acquisition rate is 50 times / second; the annual drift is less than 50PPM; the temperature drift is less than 50PPM.

7. Sealed structure to reduce dust flying.

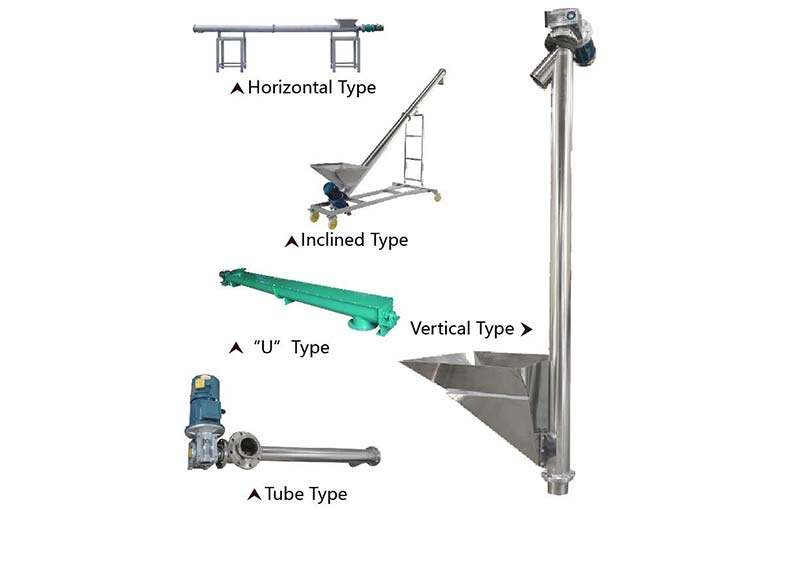

Various type:

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.

Features:

Features: