Description:

The high-frequency sieve adopts high frequency, which destroys the tension of the surface of the pulp and causes the high-speed oscillation of fine-grained materials on the sieve surface, accelerates the separation of large-density useful minerals, and increases the probability of contact with the sieve hole . As a result, better separation conditions are caused, and materials smaller than the separation particle size, especially the material attack particles with specific gravity and ore pulp, pass through the sieve holes and become the products under the sieve.

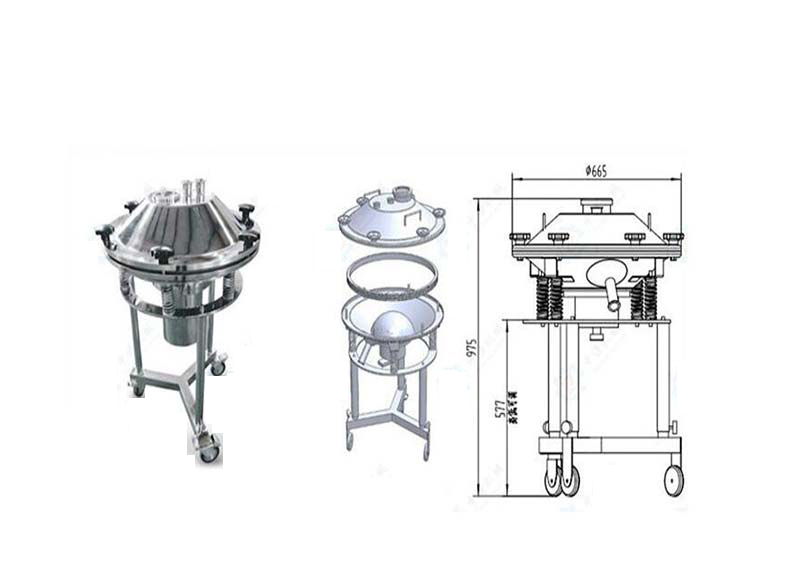

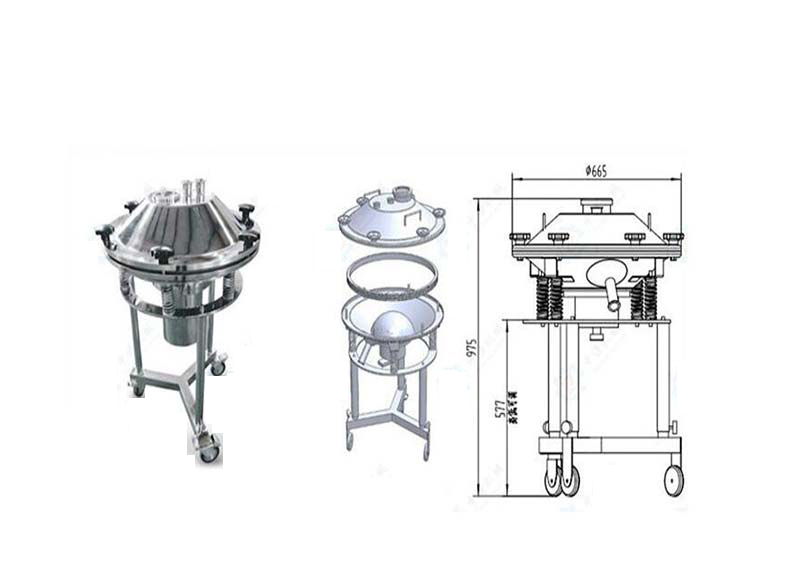

Working principle:

The ceramic mud filter screen uses an upright motor as the excitation source.Electric eccentric blocks are installed on the upper and lower ends of the motor.Adjusting the phase angle of the eccentric block can convert the rotary motion of the motor into horizontal, vertical and inclined three-dimensional motion This movement is transmitted to the screen surface.

When the upper and lower eccentric blocks are adjusted to 0 degrees, the materials are scattered from the middle to the surroundings, and are used to screen a large amount of rough materials.

When the upper and lower eccentric blocks are adjusted to 15 degrees, the material path is spirally dispersed and used to screen general materials.

When the upper and lower eccentric blocks are adjusted to 45 degrees, the materials are dispersed in a rapid vortex and used to screen fine materials.

When the upper and lower eccentric blocks are adjusted to 90 degrees, the materials are concentrated from the surroundings to the middle and filtered by wet type.

Application:

Food industry: soy sauce, vinegar, soy milk, fruit juice, pineapple juice, rice wine, rice wine, okara, yeast liquid, beverages, etc.

Pharmaceutical industry: Chinese medicine slurry, western medicine slurry, pharmaceutical intermediates, etc.

Chemical industry: paints, coatings, bleach, etc.

Ceramic industry: ceramic mud, ceramic glaze, etc.

Pollution treatment: wastewater, waste oil, pig urine, dyeing and finishing wastewater, etc.

Papermaking industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, waste water recovery, etc.

Environmental protection: garbage, human waste, waste oil, food waste water, waste water processing, etc.

Technical parameters

|

Model |

Power |

Diameter |

Excitation force |

|

GZG-600 |

0.25kw |

560mm |

5000N |

|

GZG-800 |

0.55kw |

760mm |

8000N |

|

GZG-1000 |

0.75kw |

1000mm |

10000N |

|

GZG-1200 |

1.1kw |

1130mm |

15000N |

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.