Description:

The vibration platform is also called the vibration table, which is divided into three types: vibration platform, three-dimensional vibration platform and airbag vibration platform. Vibration platform is widely used in metallurgy, mold, food, chemical, building materials and other industries. The working principle of the vibration platform is to transform the granular and powder materials from bulk to bulk and shape in the production process.

Structure:

1. The vibration platform is mainly composed of four parts: support, table, vibration mechanism and shock absorption mechanism. Driven by the vibration mechanism to do horizontal, vertical, up and down three-dimensional vibration, so named.

2. The vibration mechanism of the vibration platform is mainly composed of several vibration motors and transmission plates. The number of vibration motors is generally an even number, such as: 4, 6, 8, 10, etc. The model of the vibration motor determines the main technical parameters of the three-dimensional vibration platform .

3. The damping mechanism of the vibration platform is mainly composed of damping springs, which are divided into rubber springs, compound springs, inflatable springs, etc.

Features:

1. During the use of the vibration platform, you can adjust the excitation force of the vibration motor to achieve the ideal form of the materials on the platform.

2. Vibration motor is the source of excitation, low noise, low power consumption and simple maintenance.

3. The structure of ZDP series vibration platform is simple. Reliable operation, light weight, small size and easy installation.

4. The vibration platform is divided into three vibration modes: up and down vibration, spiral vibration and three-dimensional vibration.

5.Simple structure, reliable operation, light weight, small size and easy installation.

6.High power, large table top; maximum power 7.5kw, excitation force 80KN, can carry sand box weight 8T.

7.The height of the table is adjustable, suitable for use on the assembly line.

8.Three-dimensional vibration, suitable for complex cavity castings.

9.Stepless speed change, in the modeling process, the best compaction effect can be obtained without harming the model.

10.Self-locking function can ensure accurate positioning on the production line.

Technical parameter:

|

Model |

Area(M3) |

KW |

Amplitude |

Weight |

|

ZDP-500*500 |

0.25 |

2*0.25 |

2-5 |

300 |

|

ZDP-1000*1000 |

1 |

2*0.4 |

2-5 |

600 |

|

ZDP-1200*1200 |

1.44 |

2*3 |

2-5 |

1600 |

|

ZDP-1500*1500 |

2.25 |

2*3 |

2-5 |

2600 |

|

ZDP-3000*3000 |

9 |

6*1.5 |

2-5 |

3200 |

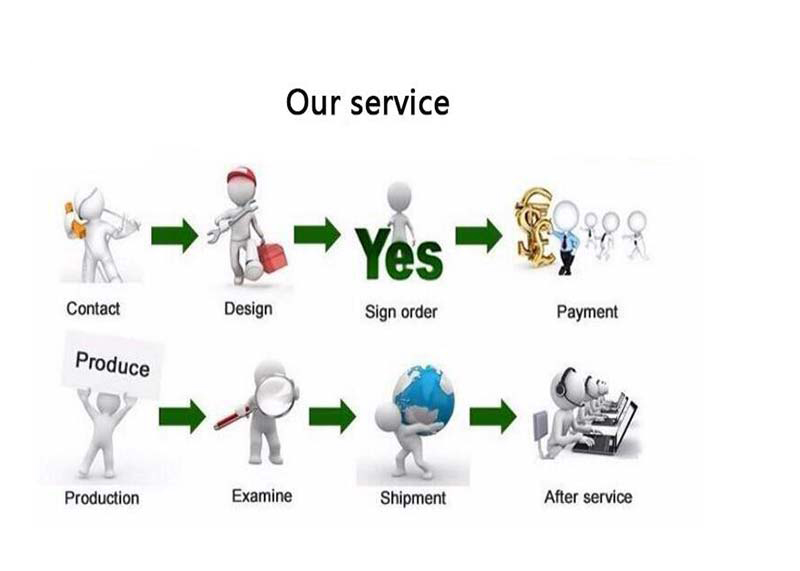

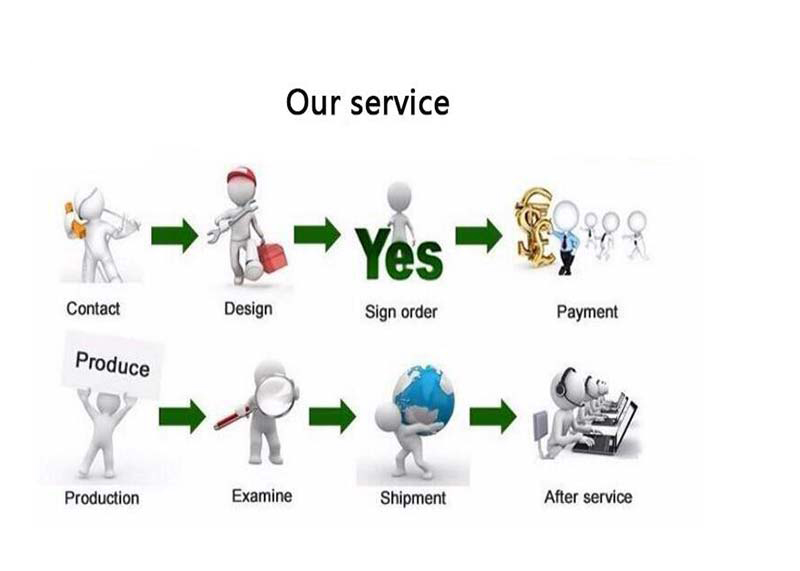

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.